Flexo Printing | Which material gives the best results?

For manufacturing and printing businesses looking for suitable printing technology, the question “What materials can Flexo be printed on?” is often asked. Each type of material brings its own benefits and applications, contributing to enhancing product value and meeting diverse market needs. In this article, let’s learn about the popular materials used in Flexo printing technology with Nam Viet Barcode.

Flexo printing on paper

One of the most common applications of Flexo printing is on paper. Papers such as Kraft, Couche, Bristol, Ivory, and Duplex are all popular. Kraft paper, with its high strength and tear resistance, is an ideal choice for paper bags and eco-friendly packaging.

Couche paper has a smooth surface and excellent printability, suitable for advertising products, leaflets, and labels. Bristol and Ivory papers have a stiff and smooth surface, suitable for high-end products such as gift boxes and cards. Duplex paper, which has one white side and one gray side, is often used in the production of product packaging and gift boxes that require high durability.

Carton

Flexo printing on cardboard is a popular choice in the packaging industry. Cardboard can be either corrugated or flat, allowing for a wide variety of product packaging. Corrugated cardboard is often used for shipping packaging due to its protective properties, while flat cardboard is used for consumer packaging, providing both product protection and a professional look.

Flexo printing on plastic

Plastic is a flexible printing material in Flexo printing technology, especially Polyethylene (PE) and Polypropylene (PP). PE plastic is often used for plastic bags and packaging due to its flexibility and water resistance. PP plastic with high mechanical strength and good heat resistance is used for food packaging, labels and durable packaging products. Polyester plastic (PET) is also popular due to its transparency, high durability and excellent water resistance.

Metal

Flexo printing on metal is an effective solution for products that require durable and attractive labels. Metals such as aluminum are often used to produce packaging such as cans, boxes, and other household items. With its high-quality printing capabilities, Flexo on metal produces products with sharp images and vivid colors, while ensuring durability and resistance to environmental factors such as humidity and temperature.

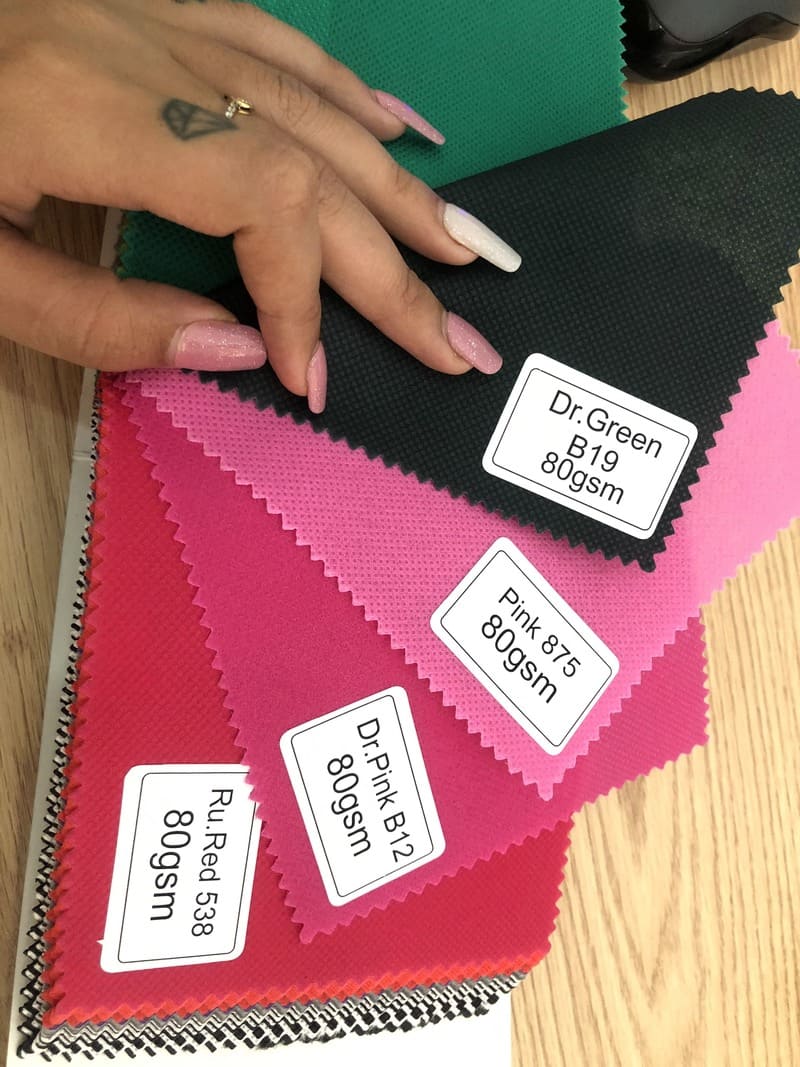

Flexo printing on fabrics and non-woven fabrics

Flexo printing is applied to a variety of materials, including fabrics and non-woven fabrics. This extends its applications to the production of fabric labels, fabric packaging, and fashion products. Fabrics and non-woven fabrics are flexible, durable, and easy to print, making them suitable for products that require aesthetics and durability, such as fabric bags, logo T-shirts, and clothing labels. Flexo printing is also used in the production of masks and personal protective products.

Film

Plastic films, including PVC (Polyvinyl Chloride), BOPP (Biaxially Oriented Polypropylene), and Shrink Film, are quite popular materials in Flexo printing. PVC film is durable, flexible, and water-resistant, suitable for labels and plastic packaging. BOPP has good transparency and strength, and is often used for products that require sharp printing and bright colors. Shrink Film is used for packaging, protection from dirt and moisture, and creating beautiful packaging.

Flexo Printing on Aluminum Foil

Aluminum foil is commonly used in Flexo printing for packaging of food, pharmaceuticals, and special preservatives. Aluminum Foil is water-resistant, light-resistant, and retains heat well, helping to protect the product inside from environmental impacts.

Flexo printing on aluminum foil delivers sharp images, vibrant colors, and long-lasting print quality. Aluminum foil is also used in labels and other metallic packaging, creating a luxurious and professional look.

In short, understanding the capabilities of Flexo printing on different substrates is important to choose the right printing method. From paper, cardboard, plastic, metal to fabric and film, each material has its own characteristics that help create high-quality and sustainable printed products.

Share: